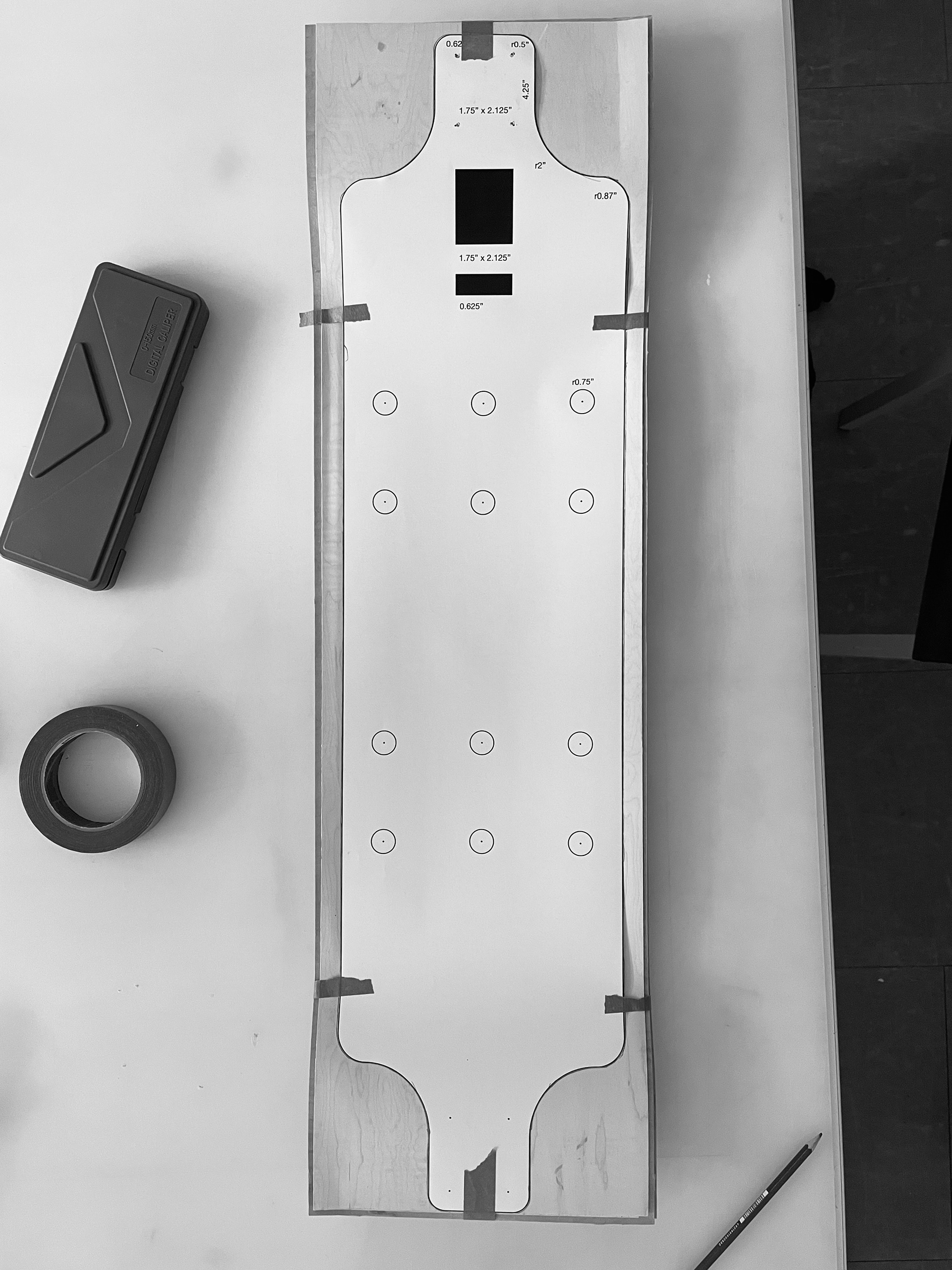

The Long(O)board is a hybrid longboard that was designed with urban commuting and portability in mind.

As different forms of last-mile transport become more popular, consumers are looking for a wider variety of options.

The hole patterns running along the edges of the board allow a strap to be attached to the board. This strap can be cinched tight to the board when riding. When not riding, the strap can be extended and worn over one shoulder.

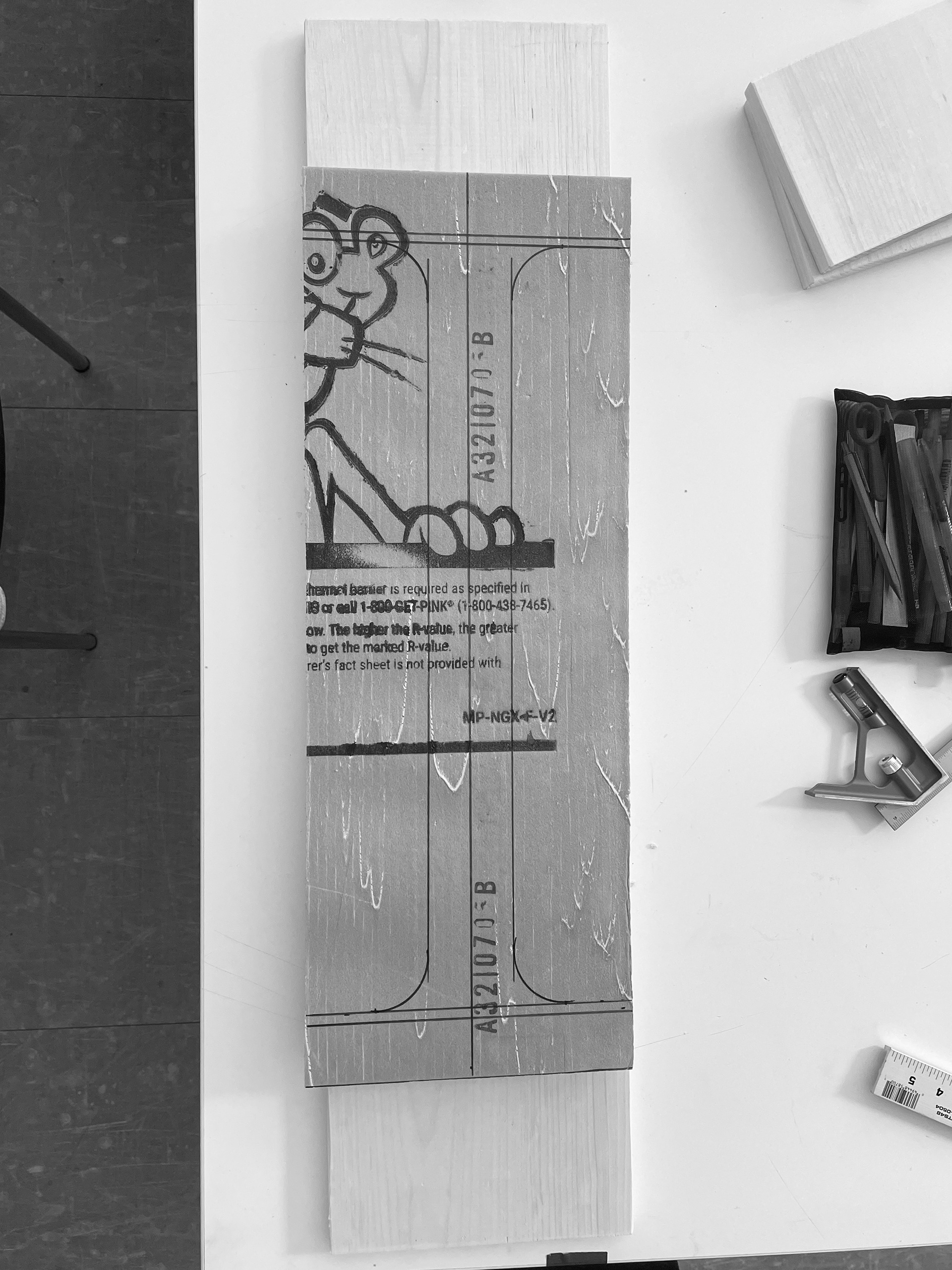

The finished board rides low to the ground and is shorter than the majority of longboards. This makes the board easier to ride and transport. The shorter length also allows less veneer to be used in construction, decreasing the overall weight. TKP trucks were used to ensure that the wheels don't extend past the edge of the board allowing for more comfortable pushing.